When you’re building your own greenhouse curtain system you want to make sure it’s of good quality and will last you for years to come. That means being careful of each step of the production to guarantee that the final product would work excellently and durable. Here At Huaya, We are Committed to Delivering The best gear that gets you there We are dedicated to the best gea We are dedicated to the best gear. Of course, greenhouse curtain gear is more than just fabric and we want to walk you through what makes up the construction of our gear that goes beyond the raw materials and the process to ensure every step along the way is right.

A detailed description of the process of manufacture of greenhouse curtain gear

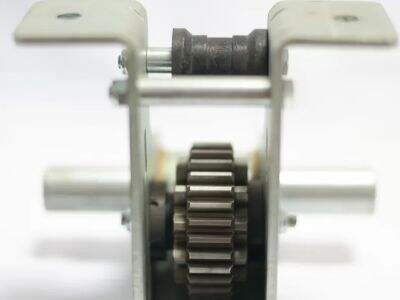

There are several items that are pretty much mandatory to make greenhouse curtain gear. First and foremost, the materials must be chosen to last and to perform. At Huaya, we only use the highest quality materials available to produce equipment that can stand up to day to day use in the greenhouse.

After the materials are selected, the gear is to be designed in such a way as to both attain the best gear power window performance and ease of use. Our team of professional engineers design everything to be practical and efficient, and that same philosophy applies to our greenhouse curtain gear, which is easy to operate and maintain.

Quality and reliability as it pertains to greenhouse curtain gear production

At Huaya, quality and reliability are the heart of what we do. To make sure that our greenhouse curtain gear excels in quality, we have established a strict quality control system at all stages of the production process. From the raw materials to the finished products we cover quality from all aspects to ensure that our window gear is as strong as you need it to be from the inside out.

The leading procedure to the adjustable reversible operation process in greenhouse curtain gear manufacturing

In order to manufacture good quality greenhouse curtain gear, the operation process should be proceeded in a systematic manner and carried out in a constant and accurate operation. At Huaya, we have established a number of important steps helping us to keep a reliable production in meet to end-process. These are steps like the strict scrutiny of materials, the right form of assembly, the faultless testing of each and every product and the perfection of the response that follows.This is how we managed to avoid the customer’s drift over the years.

Production quality control of greenhouse curtain gear

Quality control is an important component of greenhouse curtain gear production. At Huaya, we have established comprehensive QC and QA programs that monitor and inspect the entire production process. This includes inspecting incoming materials, random product testing, and in-process monitoring so we can be confident that the gear coming out of our facility, is meant for the world you want to play in.

Why is a Quality-Focused Attitude Important in Manufacturing Greenhouse Curtain Gear?

Quality is critical when selecting a value-added approach to greenhouse curtain gear manufacturing. It is first and foremost to be sure that the gear will function according to the specifications and the customer requirement. Secondly, it has implications for trust and credibility among the customers who depend on our gear to keep their greenhouses functioning. Last but not least, quality creates less defective product and fewer returns, avoiding wasted time and money over the long haul.

Table of Contents

- A detailed description of the process of manufacture of greenhouse curtain gear

- Quality and reliability as it pertains to greenhouse curtain gear production

- The leading procedure to the adjustable reversible operation process in greenhouse curtain gear manufacturing

- Production quality control of greenhouse curtain gear

- Why is a Quality-Focused Attitude Important in Manufacturing Greenhouse Curtain Gear?

EN

EN